Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System

An elastomeric waterproofing system that uses TetraCrete® and other proprietary components. Designed for walking decks and roof coverings with ICC ESR-3672 certification for Class B fire rating. Perfect for residential and light commercial applications.

Key Benefits

Code Compliant

ICC-ES listed (ESR-3672)

Class B Fire Rated

Meets fire safety standards for walking decks

Weather Resistant

Superior protection against harsh weather

Multi-Substrate

Works on plywood, concrete, and wood

Recommended Applications

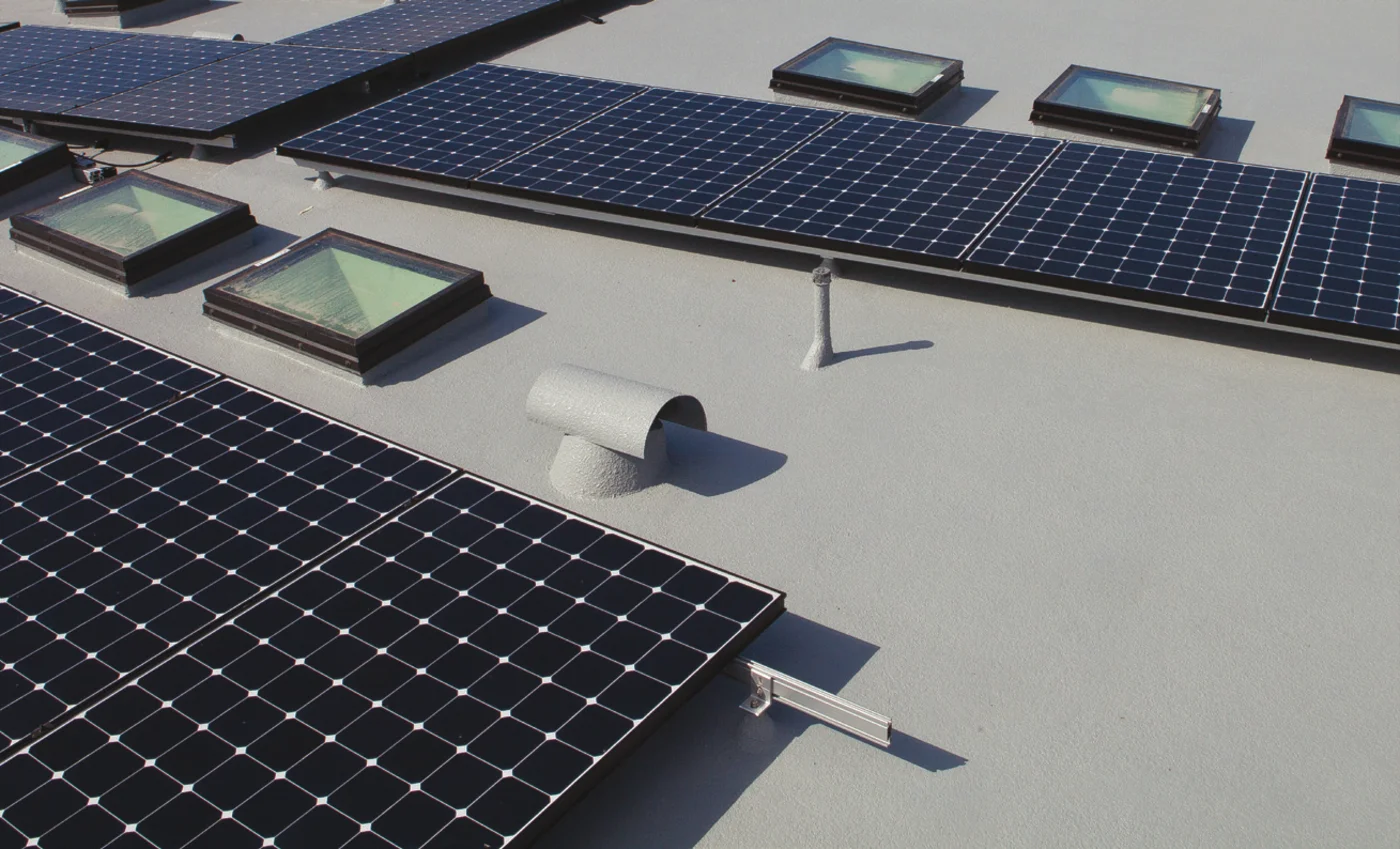

Professional finished deck surface

Commercial installation example

Technical Specifications

Coverage Rates

Dry Times

Minimum Thickness

TetraCrete application requires a minimum thickness of 1/16" for proper performance.

Building Code Compliance

ICC-ES evaluated under AC39 Acceptance Criteria for walking decks

IBC International Building Code

Compliant with IBC editions:

IRC International Residential Code

Compliant with IRC editions:

California State & Los Angeles Compliance

ESR-3672 includes official City of LA Supplement and California Supplement for direct code acceptance.

Powered by TetraCrete®

Our concrete system delivers four key properties for superior performance

Fire-Resistance

Meets or exceeds stringent building code fire standards

Flexibility

Elastomeric properties accommodate structural movement and thermal expansion

Durability

Perfect for residential and light commercial foot traffic

Weather-Protection

Resists UV rays, rain, extreme temperatures, and freeze-thaw cycles

Application Instructions

Plywood Deck Installation (8 Steps)

Surface Preparation

Clean and prepare the plywood deck surface, ensuring it's dry and free of debris.

Seal Joints

Apply sealant to all joints, edges and seams to prevent water infiltration and leakage.

Apply Base Coat

Apply base coat at 60-75 sq ft per gallon coverage rate.

Embed Fiberglass

Install fiberglass reinforcement in wet base coat for added strength.

Apply TetraCrete Mixture

Apply TetraCrete at 70-85 sq ft/gallon with minimum 1/16" thickness.

Texture Coat Application

Spray texture coat at 90-100 sq ft per gallon for desired finish.

First Top Coat

Apply first top coat at 150-180 sq ft per gallon.

Second Top Coat

Apply final top coat for complete protection and beautiful finish.

Concrete Surface Installation (6 Steps)

For concrete surfaces, the process is simplified to 6 steps, following a similar coating progression with adjustments for the concrete substrate.

Frequently Asked Questions

What is the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System?

The Deck Flex W.F. Fire Retardant System is a walking deck and roof covering system. It is a coating system designed for use, without metal lath, over exterior-grade plywood substrates. It can also be used on concrete decks. When installed as described in Section 4.3 of ESR-3672, it is used as a Class B roof covering.

What is the fire rating for the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System?

When the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System is applied as described in Section 4.2.2 of ESR-3672 on a plywood or concrete deck with a maximum slope of 1/4 inch to a horizontal foot (2.1 percent slope), the system has a Class B roof classification.

Can the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System be applied to concrete?

Yes, the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System is evaluated for use on both concrete decks and plywood surfaces. It provides a Class B fire rating. For applications requiring a Class A fire rating over plywood substrates, see our Deck Flex W.M. Walking Deck & Roof Covering Waterproofing System.

What is the material mixing ratio for the texture coat in the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System?

The Deck Flex Texture Coat is a mixture of TetraCrete No. 2 White and TetraCrete Additive. It is mixed to a pasty consistency at a ratio of 45 to 50 pounds (20.4 to 22.7 kg) of TetraCrete No. 2 White to one gallon (3.8L) of TetraCrete Additive.

What are the material coverage rates for the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System?

Deck Flex Base Coat: 60 to 75 square feet per gallon. Deck Flex Texture Coat (Trowel Layer): 70 to 85 square feet per gallon. Deck Flex Texture Coat (Spray Layer): 90 to 100 square feet per gallon. Deck Flex Top Coat: 150 to 180 square feet per gallon.

What are the required dry times between coats for the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System?

Deck Flex Base Coat: Must dry for two to four hours. Deck Flex Texture Coat: Must dry for one to two hours.

What are the substrate requirements for the Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System?

The Deck Flex W.F. Walking Deck & Roof Covering Waterproofing System is evaluated for use over exterior-grade plywood and concrete decks. Plywood substrates must be a minimum of 5/8 inch (15.9 mm) thick. All substrates must be structurally sound, free of contaminants (like water, paint, bond breakers), free of projections or depressions, and sloped for proper drainage. All plywood joints must be over framing members or blocked with minimum 2-by-4 blocking. For detailed specifications, see our technical specifications page.

Technical Documentation

ICC-ES ESR-3672 Report

Class B fire rating certification and code compliance

Learn about AC39 Acceptance Criteria

Download PDFRelated Resources

Fire Ratings Explained

Understand Class A vs Class B fire ratings and when each is required for your project.

How to Choose a Deck Coating

Compare different coating types and learn when a professional waterproofing system is the right choice.

California SB 721/SB 326 Compliance

How ICC-ES listed systems simplify compliance with California balcony inspection requirements.

What is Elastomeric Roof Coating?

Learn about elastomeric coatings for roof restoration and energy efficiency.